Load-optimised design of cutting edge microgeometries for internal turning processes

| E-Mail: | pillkahn@ifw.uni-hannover.de |

| Team: | Philipp Pillkahn |

| Year: | 2022 |

| Funding: | German Research Foundation (DFG) Knowledge Transfer |

| Duration: | 01/22 - 08/24 |

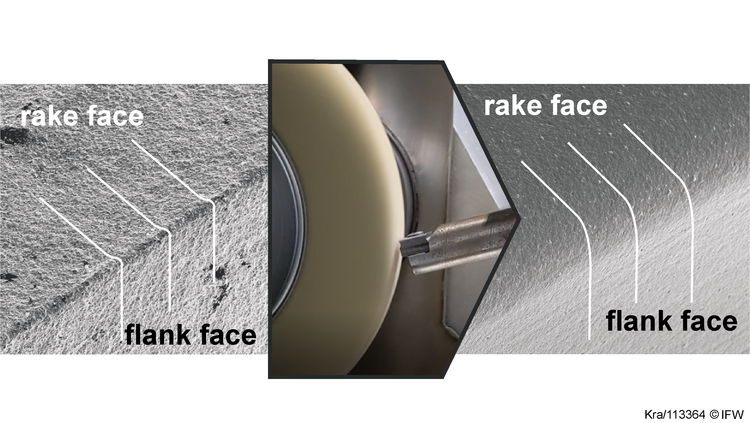

The cutting edge microgeometry can significantly improve the application behaviour of cutting tools and considerably increase productivity and process reliability. A load-specific design method for the cutting edge shape enables cost-reduced and more efficient tool development for internal turning. The basic mechanisms of impact are known, but have not yet been transferred to the industrially relevant field of internal turning. The transfer of the scientific results to the design of the brushing process is also still to be realised.

Knowledge of the loads during internal turning allows an application-specific cutting edge design for industrial processes and use in tool development. Targeted cutting edge preparation can increase the cutting edge stability and thus lead to an increase in performance, especially for specialised tools. Furthermore, an industrial design of the brushing process allows customer and process-specific cutting edge micro-geometries to be offered from batch size 1 at a reasonable cost.

Objective of the project

In the project, we gained knowledge about the thermo-mechanical load collective in the cutting wedge during internal turning in order to develop a load-optimised cutting edge design method. For this purpose, the mechanical and thermal loads in the cutting process were recorded and the prevailing stresses in the cutting wedge were simulated as a function of the cutting edge microgeometry. This enables a load-optimised design of the cutting edge microgeometry, taking into account the process temperatures. In combination with the newly developed process design for the industrial use of brushing, customer and process-specific cutting edge microgeometries for internal turning can be offered with a short time-to-market and increased performance.

Advantages for companies

- load-optimised cutting edge microgeometry - Customer and process-specific cutting edge microgeometries

- increased performance of specialised tools - longer tool life reduces non-productive times and increases productivity

- shortened time-to-market - design model for industrial utilisation of brush cutting

Procedure

In the DFG knowledge transfer project “Load-optimised design of cutting edge microgeometries for industrial processes”, we researched and developed a design method for load-optimised cutting edges for internal turning together with MAPAL Dr. Kress KG. For this purpose, the mechanical loads were determined using the simultaneous measurement system of micro-cinematography and process force measurement and the stress distribution on the cutting wedge was simulated. Furthermore, the temperature fields in the tool were determined as a function of the cutting edge microgeometry by means of in-situ temperature measurements.

You are also interested in a co-operation project?

Contact Philipp Pillkahn by e-mail at pillkahn@ifw.uni.hannover.de or by phone at +49 511 762 5389.