Development of a force-based electric feed unit and process monitoring for mobile wire saws

© IFW, Rahner

© IFW, Rahner

| Led by: | Prof. Dr.-Ing. Berend Denkena |

| E-Mail: | Rahner@ifw.uni-hannover.de |

| Team: | Björn-Holger Rahner |

| Year: | 2019 |

| Date: | 04-12-20 |

| Funding: | ZIM |

| Duration: | 06/2019-11/2021 |

| Is Finished: | yes |

| Further information | Projektpartner: Cedima Diamantwerkzeug- und Maschinenbaugesellschaft mbH |

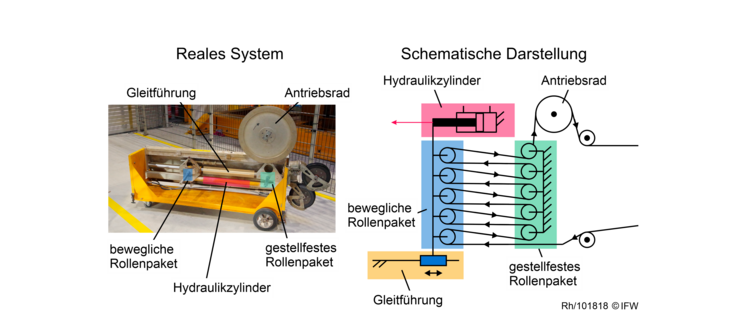

Mobile rope grinding often involves separating large-volume components from one another. The tool used consists of a rope with diamond-studded cutting beads. The two ends are connected to each other to form an endless rope (comparable to a string of beads) and wrap around the workpiece. As a result of the rope speed (relative movement between moving abrasive rope and stationary workpiece) and the pressure force of the cutting beads on the workpiece, the workpiece is separated. Typical rope speeds are between 20-30 m/s. Nowadays, the cutting process is only controlled and monitored by the machine operator, which means that the productivity, process reliability and safety of both man and machine are largely dependent on his experience. This represents a significant disadvantage in terms of cost and safety. Another disadvantage of mobile wire saws is the generation of the pressure force. For this purpose, feed units are used which, in addition to taking up the released cutting wire, also realize the wire tension. The force is often generated hydraulically or pneumatically. The disadvantage of this is that additional units are required, which reduces mobility and increases costs. Existing electric feed units, however, only work with speed control, which means that the cutting rope is often mechanically overloaded, depending on the progress of the process. This cannot occur due to the principle-based force control of hydraulic and pneumatic actuators.

Accordingly, the aim of the project is on the one hand to increase process reliability and on the other hand to implement an all-electric mobile wire saw. For this purpose, measuring systems for process monitoring of the tool and the wire force are being developed and researched. The aim is to identify tool faults at an early stage, for example before a rope breaks, and to stop the process. Knowledge of the effective rope force, on the other hand, is used for force-based control of the electric feed unit.