Graded grinding wheel - operational behaviour of sintered metal bonded diamond grinding wheels with abrasive grain concentration gradients

| E-Mail: | geschwind@ifw.uni-hannover.de |

| Team: | Thomas Geschwind |

| Year: | 2022 |

| Funding: | German Research Foundation (DFG) |

| Duration: | 07/22 – 06/25 |

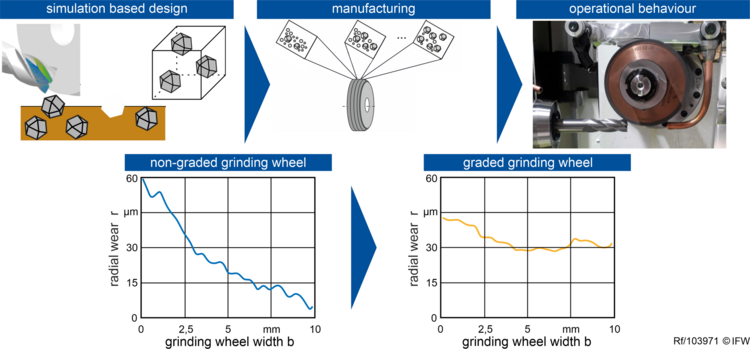

Cylindrical grinding tools are used to produce flutes on carbide shank tools. The cylindrical shape of the workpiece results in different loads across the grinding tool width. The different volumes to be machined result in different levels of wear. This increases non-productive times and therefore also production costs.

Up to now, grading has only been realised in the form of two layers. This was based on empirical tests and has already shown an improvement in wear behaviour. However, the design of the grading based on the load during grinding has not yet been considered, as there is no analytical model. In the ‘Graded grinding wheel’ project, we are using simulation software to determine the load and optimise the grading accordingly.

Objective of the project

In the project, we want to gain insights into the relationship between the manufacturing process and conditioning as well as the application behaviour. For thi, we simulate the load during flute grinding, develop a model for designing the grading and then manufacture grinding tools with grading. In the final step, we use the manufactured milling tools and investigate their application behaviour.

Advantages for companies

- Reduction of non-productive times - more uniform wear behaviour leads to fewer dressing cycles

- Increased productivity - a grain size and concentration adapted to the loads increases the feed rate

Procedure

Firstly, we design the grain concentration gradients using a removal simulation. We then work out suitable manufacturing processes that enable consistent and reliable production of grinding wheels with different material concentrations. In the next step, we investigate the preparation of these grinding wheels for use. The investigations are divided into the dressing process steps of profiling and sharpening.

Profiling is carried out mechanically with silicon carbide rollers and a rotating diamond form roller in order to determine the optimum process parameters for profile accuracy. We are investigating mechanical sharpening with regard to achieving a uniform grain protrusion. This is followed by investigations into the application behaviour of the graded grinding wheels. For this purpose, we carry out profile grinding, which we use to analyse the grinding behaviour and the thermal energy input.

Would you like to know whether this process works for you?

Contact Thomas Geschwind by e-mail at geschwind@ifw.uni-hannover.de or by telephone on +49 511 762 18849.